Precision Tools: Enhancing Accuracy in Every Task

Precision tools are the backbone of accurate work across various industries—from engineering and electronics to watchmaking and medicine. These specialized instruments are designed to offer exact measurements, detailed work, and intricate control. Whether you’re a professional machinist or a dedicated DIY enthusiast, understanding and using precision tools correctly can make all the difference in your projects.

🧰 What Are Precision Tools?

Precision tools are instruments used for tasks that require accuracy to the smallest fractions of a unit. These tools help eliminate guesswork and ensure consistency and reliability in outcomes. They are most commonly used in industries like aerospace, automotive, medical equipment manufacturing, and micro-engineering.

🔍 Benefits of Using Precision Tools

- ✅ Improved Accuracy

- ✅ Consistency in Results

- ✅ Reduced Material Waste

- ✅ Enhanced Work Efficiency

- ✅ Professional-Grade Finish

🔧 Types of Precision Tools

Here are some of the most commonly used precision tools, along with images and names:

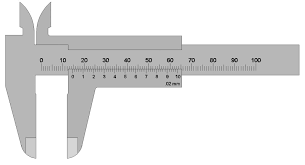

1. Caliper

Used to measure the distance between two opposite sides of an object, typically in millimeters or inches.

2. Micrometer

Offers extremely precise measurements of thickness, diameter, or depth, often used in mechanical engineering.

3. Dial Indicator

Measures small distances or angles and is used to ensure machinery alignment or runout.

4. Digital Multimeter

Used for electrical measurements like voltage, current, and resistance with high precision.

5. Torque Wrench

Applies a specific torque to a fastener, essential in automotive and industrial assembly.

6. Feeler Gauge

Thin metal blades used to measure gap widths or clearance between parts.

7. Laser Level

Projects a perfectly straight line across surfaces—crucial in construction and layout work.

8. Vernier Scale

Allows for high-precision readings between two scale markings, used in conjunction with calipers and micrometers.

9. Precision Screwdriver Set

Used in electronics and fine mechanical work where delicate handling is required.

10. Surface Plate

A flat reference plane used for inspection and layout of precise components.

🛠️ Applications of Precision Tools

Precision tools are used in many professional and technical fields:

- Mechanical Engineering: Ensures component fit and alignment.

- Medical Device Manufacturing: Requires micrometer-level accuracy.

- Watchmaking & Jewelry: Involves delicate and detailed tasks.

- Carpentry & Woodworking: Achieves clean cuts and accurate fits.

- Electronics Repair: Assembles and repairs intricate parts.

🧼 Maintenance Tips for Precision Tools

To keep your precision tools functioning at their best:

- Clean after each use

- Store in protective cases

- Calibrate regularly

- Avoid moisture and dust

- Handle with care to prevent drops or impact

📌 Conclusion

Precision tools are essential for anyone who values accuracy and craftsmanship. From simple micrometers to advanced laser levels, each tool plays a crucial role in ensuring tasks are completed to the highest standard. Whether you’re working in a professional setting or on a DIY project, investing in quality precision tools is a step toward perfection.

0 Comments